Efficient loading planning and optimal cargo placement are crucial for the logistics industry. Almost every young logistics professional has encountered the question "how many pallets can fit on a trailer?" The pallet calculator might say 34 pallets, but experienced practitioners would say 33. Many more questions arise when it comes to loading different-sized cargo, stacking methods, or unloading sequences. This is why Goodloading, a loading planning startup, has gained such popularity. With the introduction of its new version, businesses now have an even better tool for optimizing cargo space utilization, not only on trailers but also in sea containers, air freight, and on pallets.

How to effectively distribute cargo on a trailer?

Distributing cargo on a trailer is one of the most important tasks during the loading process. Many transportation operators face challenges in utilizing the available space efficiently. However, with Goodloading, this task becomes much easier and more effective.

The new logistics planner introduces advanced features for cargo distribution and scheme creation. Program users can now experiment with different distribution variants to achieve optimal use of the available space.

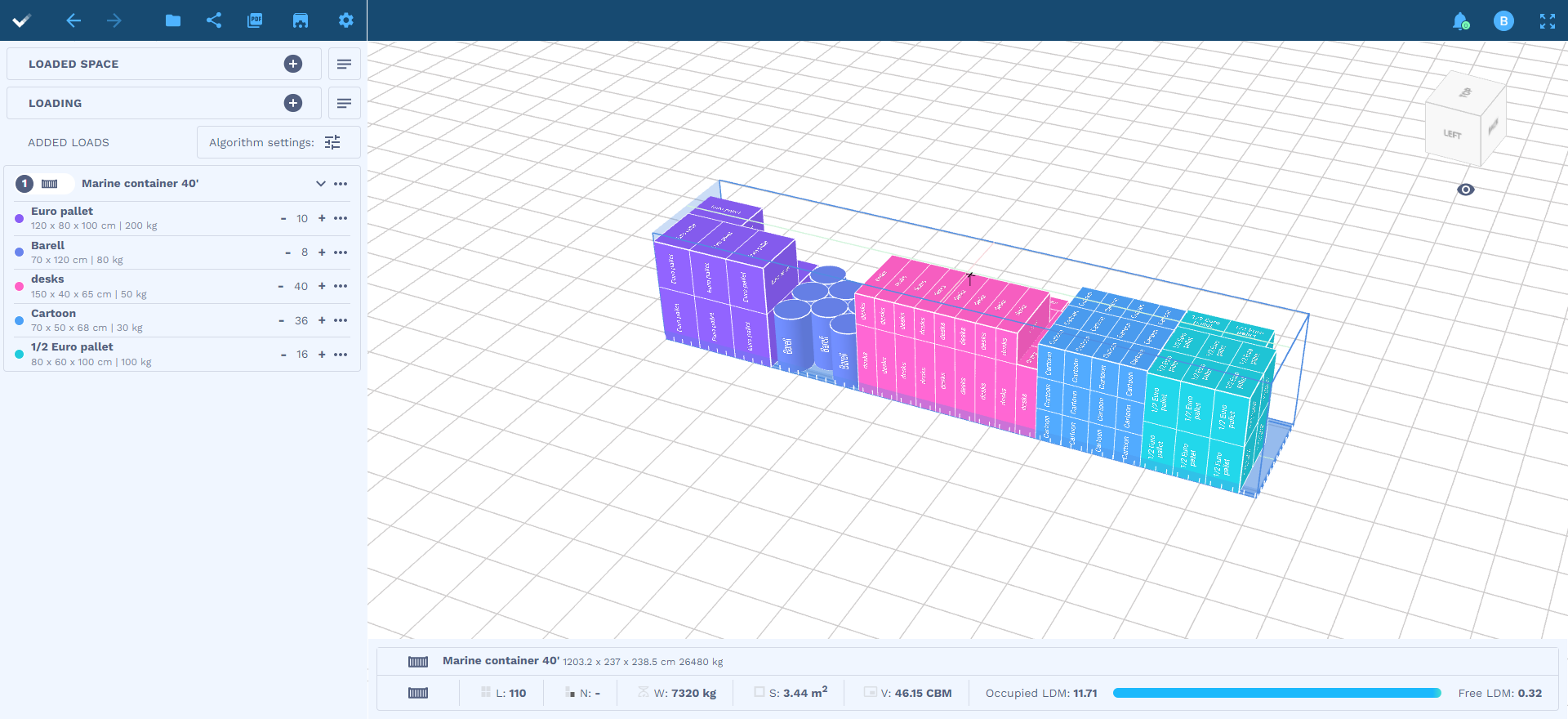

The simulator also offers the ability to optimize space utilization in sea and air containers. Containers are a popular means of transportation for many industries, but maximizing space utilization can be challenging. With the application, users can precisely plan the arrangement of not only pallets in the container but also other cargo, maximizing the available space. This leads to reduced transportation costs and increased logistics efficiency.

Cargo loading program for trailers

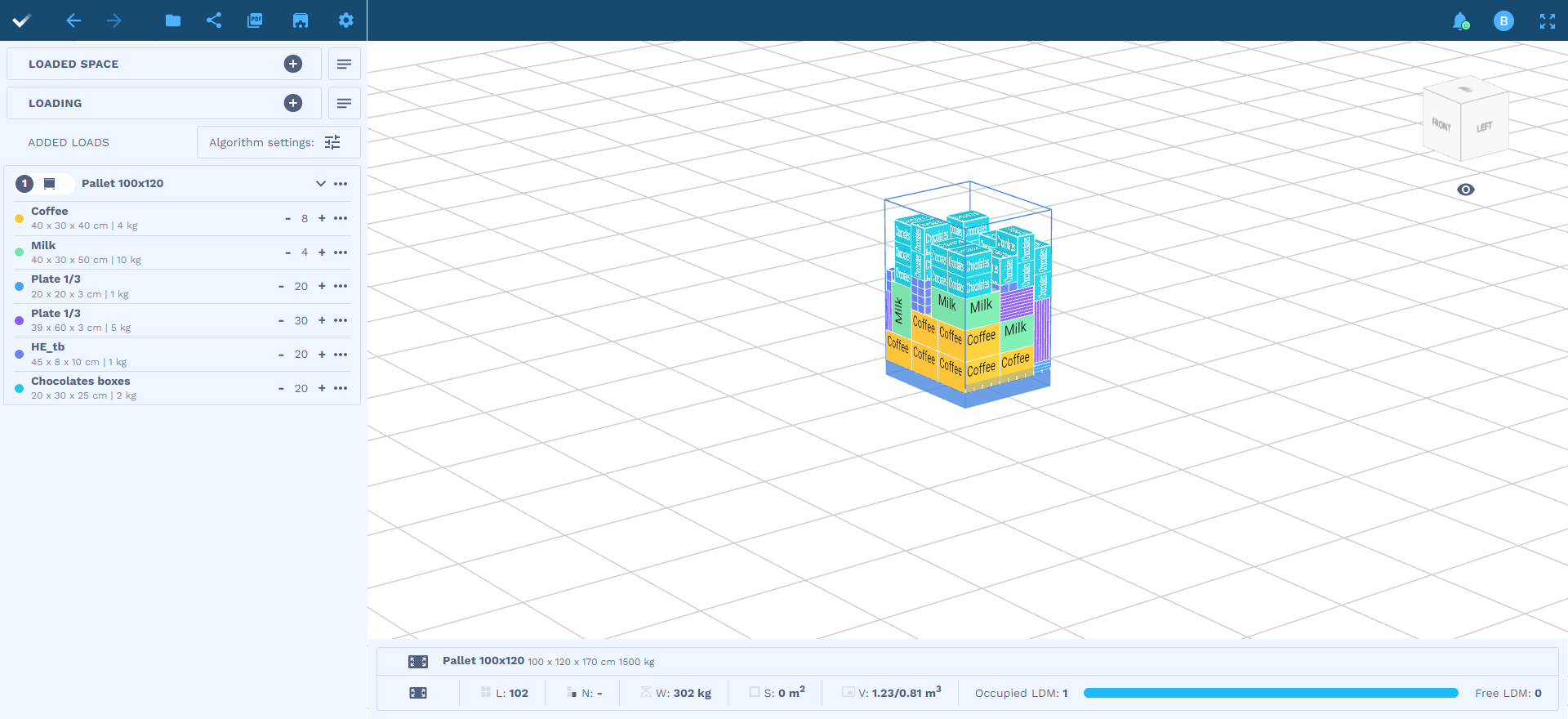

In addition, Goodloading also offers features for optimizing cargo space utilization on pallets, which may also interest entrepreneurs involved in production and warehousing. The new version of the application allows for generating pallet loading schemes that help achieve optimal space utilization on the pallet and subsequently on the chosen mode of transportation, thus reducing its costs.

How much time can you save in the logistics planning process?

Using the new version brings many benefits to businesses, including the time required for planning simulations. Customers of the Wrocław-based company report time savings ranging from 30 minutes to 2 hours every day. Above all, optimizing cargo space utilization on trailers, sea and air containers, and pallets translates into reduced transportation costs, increased logistics efficiency, and minimized risk of goods damage.

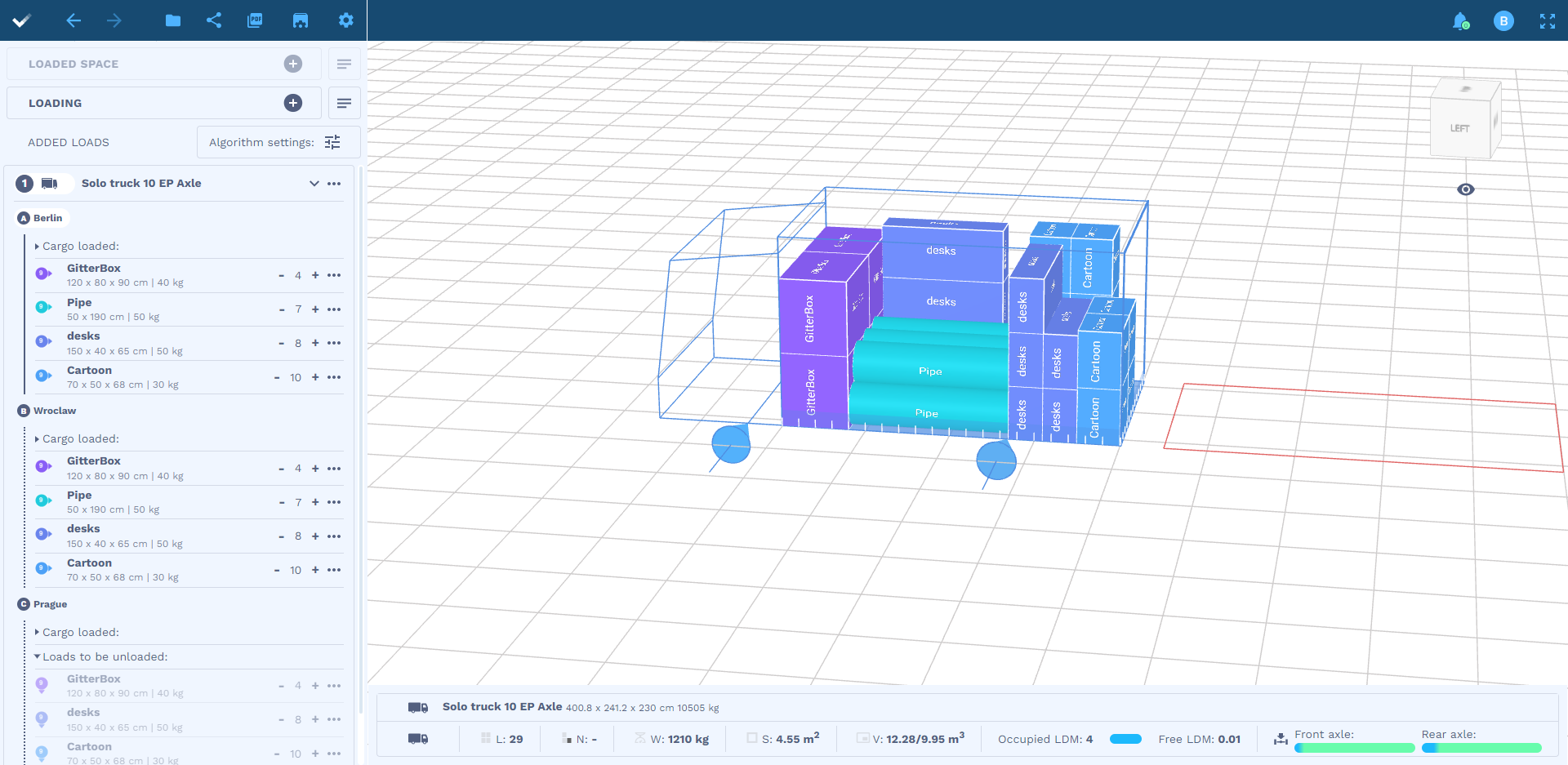

The new features of the Goodloading program facilitate easy cargo planning and scheme generation, resulting in error minimization. One of the key solutions is the introduction of a multi-stop solution known in the industry as "Milk Run."

What is the Milk Run strategy?

Milk Run is a term used in logistics that refers to an efficient method of transportation and goods delivery. It is a strategy involving simultaneous pickup or delivery of various products or materials from multiple suppliers or recipients in a single trip.

Milk Run is particularly popular in just-in-time (JIT) delivery logistics, where there is a need for regular deliveries of small quantities of different products to a manufacturing facility. By combining deliveries from different suppliers into one trip, Milk Run reduces the number of vehicles on the road, leading to transportation cost reduction and environmental pollution reduction.

The main advantages of Milk Run include reduced transportation costs, minimized downtime, and optimal space utilization in the vehicle. However, it requires proper route planning, coordination with suppliers and recipients, and understanding their delivery requirements.

What features does the new cargo loading planner have?

- Dozens of algorithms for checking optimal cargo placement

- Advanced stacking function

- Loading/unloading/transshipment points along the route

- Handling of pipes and barrels

- Cargo arrangement at any angle

- Work with air containers

- Center of gravity in a sea container

- Ability to add refrigeration units, spare tires in the vehicle, container doors, and variofloor

- Ability to place cargo longer than the cargo space

It is evident that optimizing cargo space utilization is incredibly important for logistics companies, and the new version of Goodloading provides the necessary tools to achieve this goal. With it, planning cargo loading and pallet placement on trailers, sea and air containers, and pallets becomes easier, more efficient, and cost-effective. Businesses using the Goodloading program gain a competitive advantage through optimized cargo space utilization.

more info: goodloading.com